Back >>

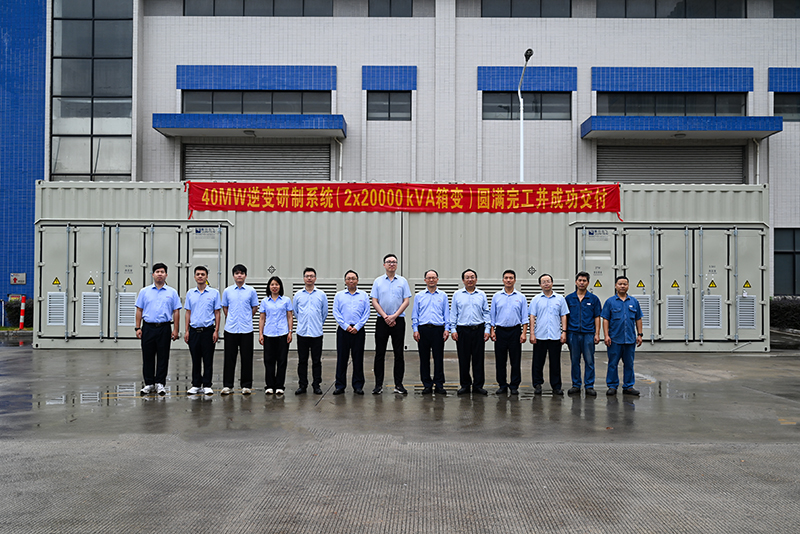

SUNTEN Successfully Delivers Ultra-High Capacity Prefabricated Substation

In mid-2024, SUNTEN was awarded the "Shenyang 40MW Inverter Project" by Changzhou Borui Company. The project required two 10kV prefabricated substations, each equipped with 20,000kVA dry-type transformers without excitation voltage regulation. The system consists of two substations operating in parallel, making it currently the largest capacity prefabricated substation product in China.

Changzhou Borui Power Automation Equipment Co., Ltd. is an important process research center and primary equipment production base for NR Electric Co., Ltd. It is reported that this project will serve the Shenyang Aeroengine Research Institute (606 Institute) under AVIC, which is China's first aeroengine design institute primarily engaged in the design and development of large and medium-sized aircraft engines, as well as gas turbine R&D tasks.

The high-capacity prefabricated substation presented increased difficulties in both product design and manufacturing processes. The substation utilizes large-capacity dry-type transformers that require special lifting equipment for installation and three-phase high-capacity fans to ensure safe and normal operation. The product features a containerized enclosure that must meet structural strength requirements for a single substation weighing over 50 tons. Additionally, the customer had stringent requirements for the high and low voltage switchgear equipment in the substation. The product is equipped with fixed switchgear for high currents of 6-10kV, with rated currents exceeding 4000A, and the switchgear must provide intelligent protection, user-friendly operation, and digital monitoring capabilities.

Facing these challenges, various departments at SUNTEN worked closely together. The sales and R&D teams proactively addressed difficulties, actively cooperating with the design institute and customers to continuously optimize the design solutions, ensuring successful project execution. By mid-November, these two high-capacity prefabricated substations were successfully completed, with all performance parameters fully meeting customer requirements, and were delivered on schedule, providing reliable support for the customer's R&D project.

The prefabricated substation adopts a modular design concept, integrating multiple functional electrical equipment such as transformers, control systems, and protection devices into a compact, transportable containerized power distribution system. Traditional substation construction typically requires over a year, while SUNTEN's prefabricated substation can reduce this period to just a few months before being transported as a complete unit to the customer's site for immediate use. This new power system can significantly accelerate project timelines and improve operational efficiency for customers.

The successful development and on-time delivery of this ultra-high-capacity, complex prefabricated substation demonstrates SUNTEN's strong technological innovation capabilities and R&D problem-solving competence, highlighting the company's leading position in power industry solutions. Moving forward, SUNTEN will continue to uphold the corporate spirit of "Integrity and Trustworthiness, Pioneering Innovation, Collective Effort, and Pursuit of Excellence," strengthen technological R&D capabilities, further expand market reach, consistently provide high-quality products and services to customers, and work with partners to promote the construction of major projects.

After over 30 years of innovation, we have formed a full series of Dry-Type transformer product lines, including SC to SCBH19 iterative models, as well as new energy equipment such as 1,500V energy storage systems.

After over 30 years of innovation, we have formed a full series of Dry-Type transformer product lines, including SC to SCBH19 iterative models, as well as new energy equipment such as 1,500V energy storage systems.  Prefabricated substations are fully functional, reliable, with low investment, small footprint, and easy installation; they have good safety and a wide range of enclosure types.

Prefabricated substations are fully functional, reliable, with low investment, small footprint, and easy installation; they have good safety and a wide range of enclosure types. In 1999, the company was the first in China to introduce the complete set of the most advanced design, process and manufacturing technology from GE in the United States, and successfully developed pad-mounted transformers with a compact structure and small size.

In 1999, the company was the first in China to introduce the complete set of the most advanced design, process and manufacturing technology from GE in the United States, and successfully developed pad-mounted transformers with a compact structure and small size. Liquid-immersed transformers utilize a highly stable insulating liquid medium, and achieve efficient power transmission through electromagnetic induction between the iron core and windings.

Liquid-immersed transformers utilize a highly stable insulating liquid medium, and achieve efficient power transmission through electromagnetic induction between the iron core and windings. Since the early 1990s, relying on the “Guangdong Provincial Urban Network Electrical Equipment Engineering Technology Development Center”, SUNTEN has developed and researched resin-insulated dry-type air-core reactors and dry-type iron core reactors.

Since the early 1990s, relying on the “Guangdong Provincial Urban Network Electrical Equipment Engineering Technology Development Center”, SUNTEN has developed and researched resin-insulated dry-type air-core reactors and dry-type iron core reactors.  In the late 1990s, SUNTEN developed an automatic tuning arc suppression coil grounding complete set that integrates primary high-voltage equipment and secondary control equipment.

In the late 1990s, SUNTEN developed an automatic tuning arc suppression coil grounding complete set that integrates primary high-voltage equipment and secondary control equipment.  Since 2002, SUNTEN has been producing complete switchgear sets, with products covering the full range of 400V-40.5kV/400A-6300A, and having authorized cabinet models of Schneider MVnex+BlokSeT and ABB MDmax.

Since 2002, SUNTEN has been producing complete switchgear sets, with products covering the full range of 400V-40.5kV/400A-6300A, and having authorized cabinet models of Schneider MVnex+BlokSeT and ABB MDmax. SUNTEN (founded in 1988) is a leading enterprise in the field of power transmission and distribution, as well as new energy equipment, with core technologies in areas such as thermal power frequency regulation energy storage, wind-solar-storage integration, and industrial and commercial energy storage.

SUNTEN (founded in 1988) is a leading enterprise in the field of power transmission and distribution, as well as new energy equipment, with core technologies in areas such as thermal power frequency regulation energy storage, wind-solar-storage integration, and industrial and commercial energy storage.

Rail transit requires efficient, energy-saving, safe and reliable power solutions to ensure the safe and punctual operation of trains, while adopting energy-saving designs to reduce energy consumption and support the construction of green and intelligent transportation.

Rail transit requires efficient, energy-saving, safe and reliable power solutions to ensure the safe and punctual operation of trains, while adopting energy-saving designs to reduce energy consumption and support the construction of green and intelligent transportation. Nuclear power plants have extremely high safety requirements for electrical equipment, which must be certified to 1E level to ensure stable operation under extreme conditions, and employ efficient and energy-saving designs to guarantee the safe and efficient operation of nuclear power plants.

Nuclear power plants have extremely high safety requirements for electrical equipment, which must be certified to 1E level to ensure stable operation under extreme conditions, and employ efficient and energy-saving designs to guarantee the safe and efficient operation of nuclear power plants. Data centers provide secure and reliable data storage and efficient computing to support the application of technologies such as cloud computing and artificial intelligence.

Data centers provide secure and reliable data storage and efficient computing to support the application of technologies such as cloud computing and artificial intelligence. The renewable energy sector such as photovoltaics requires stable power solutions to improve generation efficiency, enhance equipment environmental adaptability, and adopt energy-saving designs to reduce energy consumption, driving the green energy transition.

The renewable energy sector such as photovoltaics requires stable power solutions to improve generation efficiency, enhance equipment environmental adaptability, and adopt energy-saving designs to reduce energy consumption, driving the green energy transition. SUNTEN delivers wind power-optimized transformers and substations, backed by 35 years of R&D expertise, ensuring all-weather reliability and full lifecycle support for stable renewable energy operations.

SUNTEN delivers wind power-optimized transformers and substations, backed by 35 years of R&D expertise, ensuring all-weather reliability and full lifecycle support for stable renewable energy operations. Industrial and commercial power distribution requires efficient, energy-saving, highly reliable and stable power solutions to meet the requirements of continuous operation and various special industrial and commercial environments.

Industrial and commercial power distribution requires efficient, energy-saving, highly reliable and stable power solutions to meet the requirements of continuous operation and various special industrial and commercial environments. Power plant generators require low-harmonic distortion excitation transformers that can adapt to frequent load changes and handle short-term overloads, ensuring the reliable and stable operation of the excitation system.

Power plant generators require low-harmonic distortion excitation transformers that can adapt to frequent load changes and handle short-term overloads, ensuring the reliable and stable operation of the excitation system. In the context of the accelerating energy structure transformation, electrochemical energy storage technology, with its high energy density, fast response, and multi-scenario adaptability, has become a core engine for building a new power system.

In the context of the accelerating energy structure transformation, electrochemical energy storage technology, with its high energy density, fast response, and multi-scenario adaptability, has become a core engine for building a new power system.  As an “offshore oil and gas factory” that integrates production, oil storage, and offloading functions, FPSO’s electrical system needs to meet the stable power supply requirements in the complex marine environment, serving as the core infrastructure supporting oil and gas processing, power supply, and life support.

As an “offshore oil and gas factory” that integrates production, oil storage, and offloading functions, FPSO’s electrical system needs to meet the stable power supply requirements in the complex marine environment, serving as the core infrastructure supporting oil and gas processing, power supply, and life support. LNG carriers require efficient and safe power solutions to support the liquefaction, transportation, and storage of natural gas, ensuring the safety and efficiency of energy transportation.

LNG carriers require efficient and safe power solutions to support the liquefaction, transportation, and storage of natural gas, ensuring the safety and efficiency of energy transportation. Commercial centers have stringent safety requirements for electrical equipment, necessitating highly reliable and stable power solutions, along with efficient and energy-saving designs, to ensure the normal and efficient operation of the facilities.

Commercial centers have stringent safety requirements for electrical equipment, necessitating highly reliable and stable power solutions, along with efficient and energy-saving designs, to ensure the normal and efficient operation of the facilities. Airports demand high fire resistance performance, reliability, and robust short-circuit and short-term overload capabilities for their electrical equipment. By utilizing high-efficiency products, we enable low-carbon operations.

Airports demand high fire resistance performance, reliability, and robust short-circuit and short-term overload capabilities for their electrical equipment. By utilizing high-efficiency products, we enable low-carbon operations. Leveraging its patented technologies and professional team, SUNTEN provides customized solutions for power distribution, photovoltaic, and energy storage systems.

Leveraging its patented technologies and professional team, SUNTEN provides customized solutions for power distribution, photovoltaic, and energy storage systems. In 1999, SUNTEN undertook a major national “Ninth Five-Year Plan” research project, developing a single-phase epoxy-cast dry-type excitation transformer suitable for the Three Gorges Hydropower Station, filling a technological gap in China.

In 1999, SUNTEN undertook a major national “Ninth Five-Year Plan” research project, developing a single-phase epoxy-cast dry-type excitation transformer suitable for the Three Gorges Hydropower Station, filling a technological gap in China.

Sunten Electric Equipment Co., Ltd. is a Sino-foreign joint venture established by Sunten Electric Co., Ltd. (formerly Shunde Special Transformer Factory) and French Schneider Electric. The company was founded in 1988.

Sunten Electric Equipment Co., Ltd. is a Sino-foreign joint venture established by Sunten Electric Co., Ltd. (formerly Shunde Special Transformer Factory) and French Schneider Electric. The company was founded in 1988.  Established in 1988, through over three decades of steady development, the company has grown into a modern enterprise with a site area of 120,000 square meters and a total building area of 124,000 square meters, with a registered capital of RMB 1.09 billion.

Established in 1988, through over three decades of steady development, the company has grown into a modern enterprise with a site area of 120,000 square meters and a total building area of 124,000 square meters, with a registered capital of RMB 1.09 billion.  Learn more about SUNTEN's recent news.

Learn more about SUNTEN's recent news. From the ISO management system to industry-specific certifications, SUNTEN consistently exceeds international standards, establishing a comprehensive qualification matrix spanning R&D, production, and service operations.

From the ISO management system to industry-specific certifications, SUNTEN consistently exceeds international standards, establishing a comprehensive qualification matrix spanning R&D, production, and service operations.